Patient Photos of Ear Prosthetics

Patient Case Studies of Ear Prosthetics

Our patient flew from New York to get a partial ear prosthesis that restores the top of his partially-amputated ear. This type of ear prosthetic for the upper ear is challenging to create. It requires a multiple piece dental stone mold that must be designed and fabricated with precision. It is a challenge that we relish because it is in our nature as medical artists and within our capability as anaplastologists. We carefully plan the edges of the ear prosthesis to either be hidden in the shadows of the remaining ear anatomy or to appear as natural skin folds. We can make ear prosthesis edges so inconspicuous they are almost invisible. Even though we have advanced methods to scan and digitally manipulate and plan our project, the devil is always in the final details that we love to refine and never hurry.

This veteran underwent partial auriculectomy in which the lower half of his ear was surgically removed to eradicate basal cell or squamous cell carcinoma. We work closely with many Veterans Administration Medical Centers in states including Wisconsin, Illinois, California, Kansas, Louisiana, and New York. VAMCs no longer have in-house prosthetics restoration specialists to provide partial and complete auricular and nasal prostheses. The anaplastologist sculpted fine detail in his wax to create a beautiful rendition of the missing anatomy. He finished the prosthesis with exquisite color nuances. Finally, we instructed the patient in how to properly attach his prosthesis. We work closely with Mohs surgeons, specialists in dermatological surgery who treat skin cancers including squamous cell carcinoma, basal cell carcinoma, malignant melanoma, and other neoplasms.

We really want our patients to be happy with their new auricualr ear prosthesis, even if they relocate to another part of the country. Having multiple Medical Art Prosthetics locations around the country helps us stay close and accessible to our patients so we can follow them in their progress. The slipover ear prosthesis for our patient with microtia was originally fit and delivered in our Paramus, NJ location near Hackensack, NJ. When she moved to Los Angeles, CA our California anaplastologist was able to redesign and refit her augmentative ear prosthesis in a special Glendale, California office location.

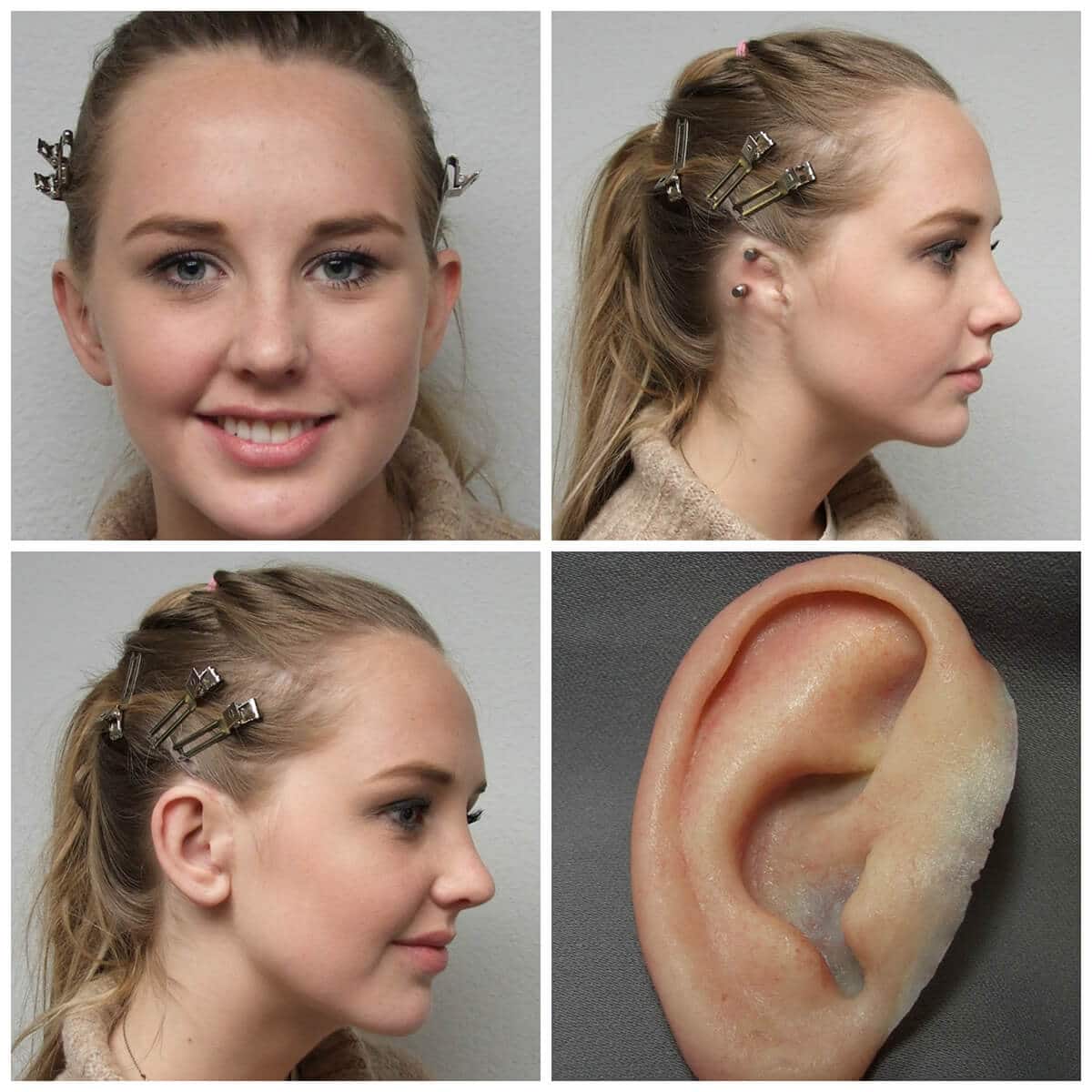

Our patient came from Atlanta, GA for the aesthetic prosthetic restoration of his partially amputated left pinna. He lost the upper portions of his helix, antihelix cartilage, and the overlying skin of his ear following skin cancer removal. Sometimes people wear their hair long to cover problems like this. Otherwise, these ear deformities from cancer surgery or accidents often make people feel conspicuous and uncomfortable when they are in situations like standing in line at the grocery store or theatre. That’s why we try so hard to match color and instill natural details that make the prosthetic ear inconspicuous or undetectable from behind or any angle. We all strive to make the perfect ear prosthetic result and outcome.

Many people born with underdeveloped ears try to have their ear restored through surgical reconstruction. They are often unhappy with their ear result. They may try repeat surgeries over many years, only to finally decide, “I want an ear that looks like my other ear, so I feel balanced and more normal – so people don’t stare anymore.†They finally decide to remove the bulky rib cartilage tissue or the Medpor ear implant. This is often the ideal time to have OI fixtures placed in the mastoid bone. These small screw fixtures solidly anchor abutments that attach the ear prosthesis using special clips or magnets. It’s a wonderful technology based on decades of proven science and predictable outcomes. How do we know this? Because our practice network and anaplastologists have been involved since 1984 as a leading innovator and provider in osseointegrated (OI) craniofacial prosthetics. Patient reports of high satisfaction with implant-retained ear prostheses are substantiated in the medical and dental literature. Our practice uses Vistafix, Southern Implant, and other implant systems in conjunction with over 25 surgeons.

Ear injuries and loss of the ear from trauma are common. People lose their ears in car or motorcycle accidents. Sometimes ears are bitten off or lost in acts of violence such as fights. We have worked with many situations where people have lost an ear from chemical burns from acid or they have had their ear bitten by a dog or horse. One man had magnetic ear implants years ago in NY, then came to us in Madison, Wisconsin for a new ear prosthesis using our scanning and 3D printing process. These photos document the “almost perfect” osseointegration magnet-retained prosthetic ear we we delivered after working with him just 3 days! The best part of the story is that he was able to receive updated retinting service in 2023 without the expense of returning to Wisconsin. This is because our network has an incredibly talented anaplastologist with offices in New Jersey now able to serve the ear prosthesis client near his home in New York. Our practice uses Vistafix, Southern Implant, and other implant systems in conjunction with over 25 surgeons.