The Ear Prosthesis Process

Conventional ear prostheses may be completed in as few as 3 days when patients stay near one of our locations. It’s a painfree process we want our patients to relax and enjoy as they anticipate their new ear!

Aesthetic ear prostheses may involve some newer technologies, but they develop at the hands of the anaplastologist who makes critical artistic judgements along the way. We instill life-like qualities into the polymerized prosthetic silicone to the point the finished ear prosthesis looks like a real living ear. The ability to create very lifelike ear prostheses is shared by very few.

Patients often find it difficult to locate a provider that specializes in prosthetic ears. Even among the many medical and dental institutions and vast health insurance networks that have an ear plastic surgeon, maxillofacial prosthodontist, dental technician, and ocularist they rarely employ a dedicated anaplastologist. We must stress that institutions have clinician teams and technologies that are impressive and some may play a role in producing ear prosthetics. However, the color accuracy and the refinement of a finished prosthetic ear must be judged by the consumer. We recommend that patients and referring physicians look for focused specialty anaplastology experience and photographic evidence of successful ear prosthetics outcomes by their practitioner.

The ear prosthetics process

If you are having the magnetic bone-anchored type of ear prosthesis (seen in this example), we make sure your abutments are clean and your hair is trimmed or lubricated so the area is ready for us to record all the details with our soft dental polyvinyl siloxane impression material. If you will have a conventional adhesive type ear or the type that slips over your microtia ear, then then the impression is even easier and faster. In any case its simple and pain-free!

Here we see the impressions of both sides: the affected side with the abutment replicas in place and the unaffected ear impression we will use for mirror imaging .

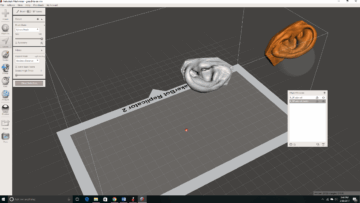

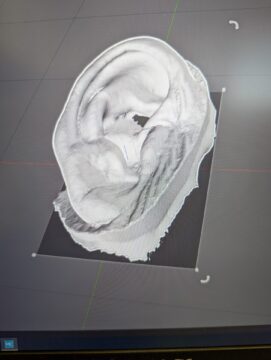

We use a scanner in some instances to capture the shape of the unaffected ear.

We create a mirror image virtual model of your unaffected ear shape.

Next the virtual model is made solid in our computer program for 3D printing of an ear prototype.

For coloration we often use silicone pigments to mix colors right in session with you. You see all the colors that go into the formulation of your unique skin color.

We painstakingly transfer our polymerized colors into our mold parts and carefully close and heat the mold to create your prosthesis.

It seems almost like magic when the ear is demolded, but the deep color blends are what we have planned for leaving minimal need for post mold color adjustment.

Every detail is important to creating your prosthesis because we want your prosthesis to be uniquely you.

The magnets in this osseointegration case pull the prosthesis into perfect position. However, the conventional adhesive type prosthesis would have the same level of accurate detailing and aesthetic result that no one will notice.